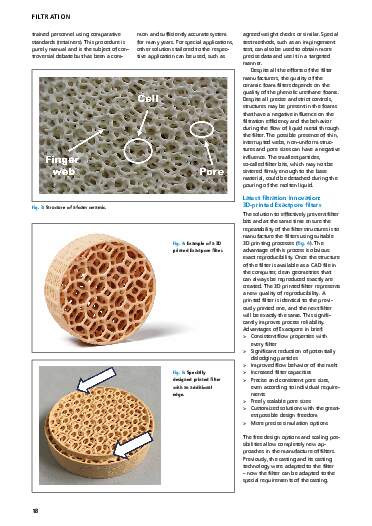

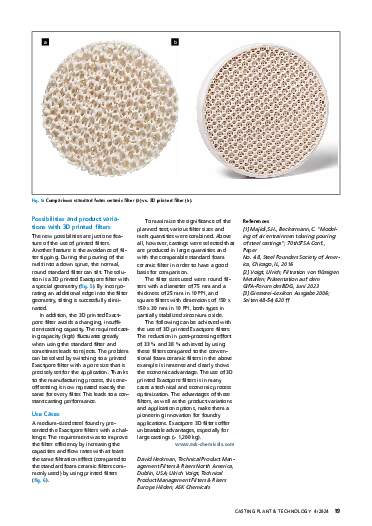

Specific pore design for improved process and quality control

The use of ceramic foam filters made of high purity oxide ceramics is state of the art in the foundry industry. The main advantage of using these filter elements is to increase foundry efficiency by reducing rework through the reduction of non-metallic inclusions in the melt.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription